Triton

FEATURES

Hardware

Kraken X-60 powered swerve drive

Full carbon fiber manipulator

Self centering system using belts

Any orientation coral intake

Carbon fiber algae scrubbers

Integrated with coral placement movement

Dual CAN System for drive train and superstructure

Dependable, reinforced wiring

Software

April tag field alignment

Fully autonomous scoring

(i.e. no human error)

Custom autos created per match

Fully student developed

Coded in Java

CREATION

Multi Discipline, Heavily Using 3D printing, Using Exclusively Polymaker Filament, CNC Milling & Routing, and manual equipment.

Rapid Prototyping and Continual Improvement

Durable Assembly Using Industry Standards.

COMPETITIONS

Canadian Pacific Regional, Vancouver, BC - Finished 2nd, Quality Award

Sundome District Qualifier, Yakima, WA - Finished 2nd, Team Spirit Award

Wilsonsville Distric Qualifier, Wilsonville, OR - Won the event, Autonomous Award

PNW District Championships, Cheney, WA - first pick of the 4th alliance - Qualified for World Championships

World Championships, Houston, TX

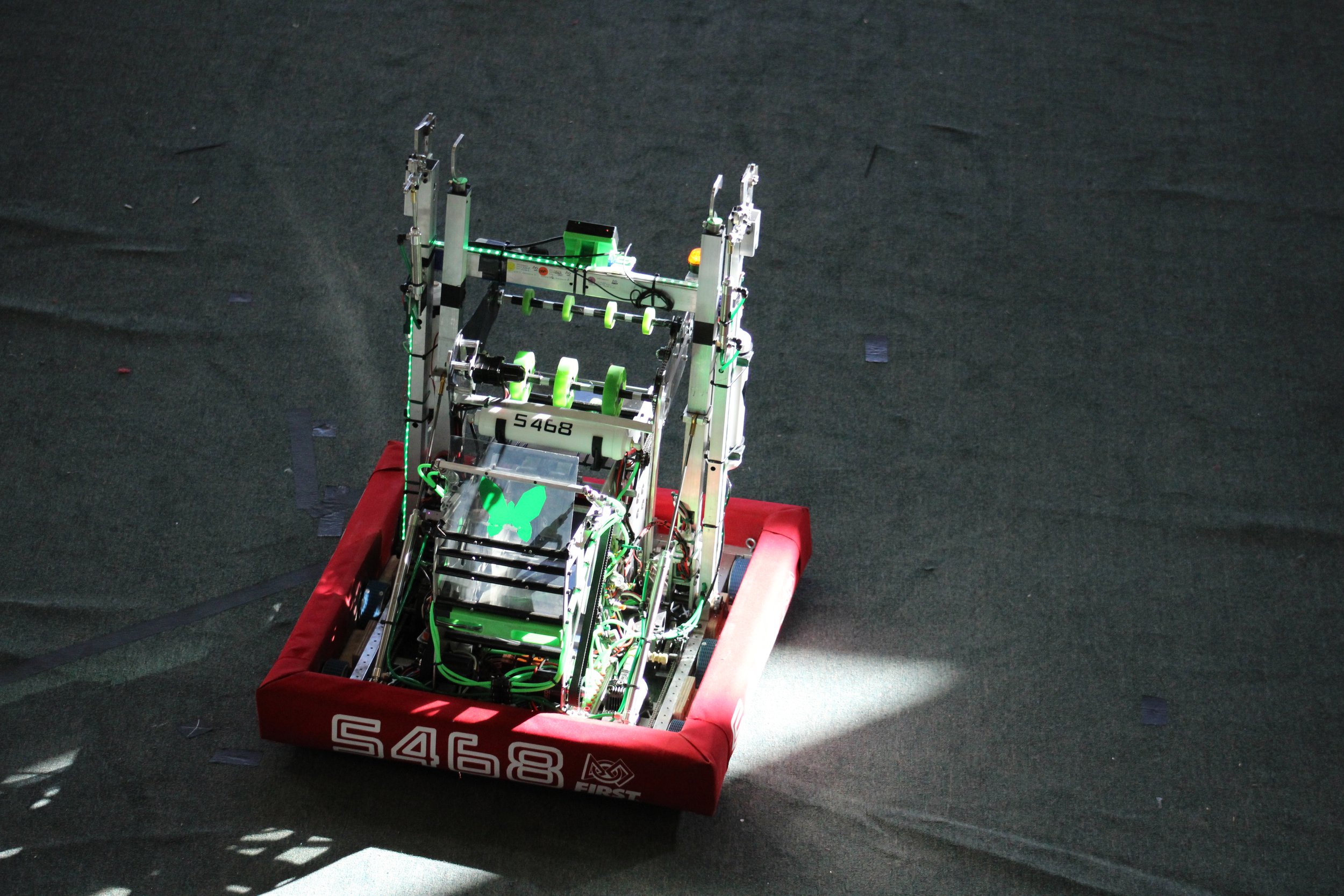

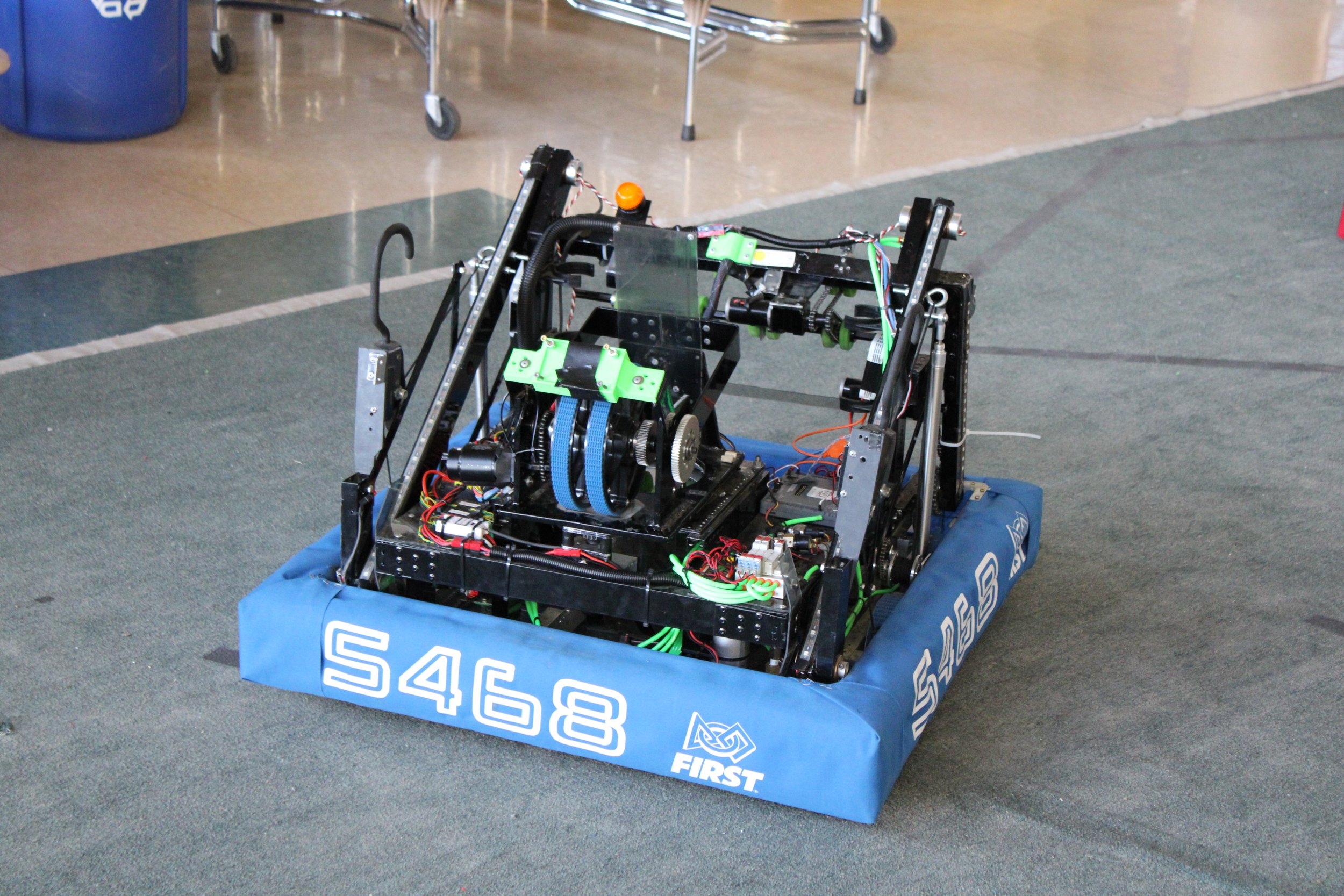

2024 HYPERION

FEATURES

Vectoring Intake Pulls Notes Into Center

Conveyor-less Handoff to Shooter

Shooter Can cover the Field Distance

First Swerve Drive On A 5468 Competition Bot

Telescoping Arm Climb

Smallest Robot We’ve Made (27”*27.5”)

Short, Capable of Going Under the Stage Core

CREATION

Multi Discipline, Heavily Using 3D printing, Using Exclusively Polymaker Filament, Water Jet Cutting, CNC Milling & Routing, and manual equipment.

Rapid Prototyping and Continual Improvement, Two Full Shooters and Six Intake Variations Built.

Durable Assembly Using Industry Standards.

Locktite on Polycarbonate free (almost).

COMPETITIONS

Albany, OR - Scrimmage - Zero Down Matches

Clackamas, OR - Team Sustainability Award

Sundome, WA - Creativity Award

FIRST Chance

Storm Surge - Rank 2

2023 APOPHIS

FEATURES

Autonomous 2 piece auto.

Autonomous charge station balance.

All position scoring capabilities, (Cone/cube low/mid/high)

6 axis of freedom.

COMPETITIONS

Clackamas, OR - Finalist - Deans List Semi Finalists

Sundome, WA - Finalist - Creativity Award Winner

Oregon State Fairgrounds, OR - Finalist - Quality Award Winner

PNW District Championships - Imagery Award Winner - Woodie Flowers Finalists Award

2022 CYGNUS

FEATURES

Custom 6 NEO shifting gearbox drive train

Color-discriminate intake

Dual Neo high goal shooter

Traversal climb

4 ball autonomous sequence

COMPETITIONS

Clackamas, Oregon - Quarterfinalist, Imagery Award Winner

Oregon State Fairgrounds, Oregon- Quarterfinalist, Innovation in Control Award Winner

Utah Regional, Salt Lake City, Utah- Semifinalist, Imagery Award Winner

FEATURES

Custom 6 NEO shifting gearbox drive train

Adjustable winching climb arms

Turret shooter with adjustable hood

Floor level intake

COMPETITIONS

Clackamas, Oregon - Quarterfinalist

Rest of season - Canceled

2020 RIGEL

FEATURES

Custom 6 NEO shifting gearbox drive train

Cargo floor intake

Panel floor intake

Hab 2 decent pistons

Level 3 rocket elevator

COMPETITIONS

Wilsonville, Oregon - Quarterfinalist, Quality Award Winner

SunDome, Washington - Semifinalist, Industrial Design Award Winner

Lake Oswego, Oregon - Quarterfinalist, Imagery Award Winner

Pacific Northwest District Championship, Tacoma, Washington - Finalist, Woodie Flowers Finalist Award Winner (Charlotte Van Valkenburg)

FIRST® Championship, Turing Division, Houston, Texas - Quarterfinalist

2019 BETELGEUSE

FEATURES

West coast pneumatic wheel drive train

Power cube floor intake

Active roller intake/eject

Chain driven elevator

Ramp

COMPETITIONS

Clackamas Academy, Oregon - Semifinalist, Team Spirit Award Winner

SunDome, Washington - Quarterfinalist

Auburn Mountainview, Washington - Event Winner

Pacific Northwest District Championship, Portland, Oregon - Quarterfinalist

FIRST® Championship, Turing Division, Houston, Texas

2018 MAYHEM

FEATURES

4 CIM west coast drive train

Dual fuel shooters

Fuel floor intake

Active gear mechanism

Climbing mechanism

COMPETITIONS

West Valley, Washington - Semifinalist, Excellence in Engineering Award Winner

Clackamas Academy, Oregon - Quarterfinalist, Imagery Award Winner

Pacific Northwest District Championship, Cheney, Washington - Judges’ Award Winner

FIRST® Championship, Carver Division, Houston, Texas - Quarterfinalist

2017 SPECTRE

FEATURES

Custom tank drive

Vacuum intake

HiGrip wheel shooter

COMPETITIONS

Wilsonville, Oregon - Semifinalist

Clackamas Academy, Oregon - Event Winner

Pacific Northwest District Championship, Portland, Oregon

2016 DOOMBA

FEATURES

Mecanum drive train

Clamping tote mechanism

Chain driven elevator

Full stack height

COMPETITIONS

Oregon City, Oregon - Finalist, Highest Rookie Seed, Rookie Inspiration Award Winner

Wilsonville, Oregon - Quarterfinalist, Highest Rookie Seed, Rookie Inspiration Award Winner

Pacific Northwest District Championship, Cheney, Washington